OEM Projects for HVAC Industry

Most of the work we do at Temco is behind the scenes development and manufacturing work for large air conditioning companies. But we’ve done work on many projects unrelated to air conditioning such as a custom wind turbine controller, sports testing equipment, a depth sounder for the commercial fishing industry a laser range finder and a floor cleaning machine controller to name a few. If you have a project that you are making already, or want to see what it would cost to have a certain widget made up to your specs, feel free to send your NDA our way and we’ll get the quote started. Our electronics, software and mechanical engineers will make your project a success. Your budget will go further which can make your product better, not just cheaper.

- Timing Gate

- Custom Relay Board

- Bacnet Boiler Controller

- Outdoor Sensor

- PWM Transducer

Timing gate project

Durable and water-resistant, the timing gate offers millisecond accuracy and multi-lane capability. With instant feedback, reaction arrows, and wireless integration, it enhances athlete training. Its 24-hour rechargeable battery, bright LEDs, and continuous synchronization ensure reliability, while versatile test creation suits all sports.

Features successfully implemented:

- Impact and water resistant

- Millisecond accuracy

- Multi-lane capable

- Instant feedback

- Wireless system integration

- Reaction test directional arrows

- Rechargeable 24-hour battery life

- Superbright LED indicators

- Continuous synchronization

- Versatile test creation for all sports

Future improvements:

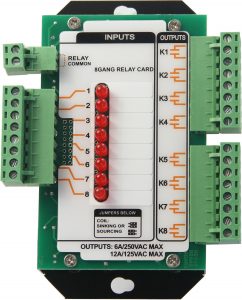

Custom Relay Board

The custom relay board works with both positive and negative ground systems, offering flexible operation through configurable jumpers.

In addition, it supports modes like common switched 24VAC or dry contact, while also featuring a panel-mount base with a removable faceplate. Moreover, it includes an LED for low-voltage relay indication, ensuring clear and reliable operation.

Features successfully implemented:

-

Works with positive and negative ground systems

-

Jumpers can set to two different operations

-

Modes: common switched 24VAC or dry contact

-

Panel mount base, removable face plate

-

LED for low voltage relay

Future improvements:

Bacnet Boiler Controller

The Bacnet Boiler Controller not only allows high-voltage pumps to connect directly with no external relays, but its passive baseplate and removable lid also house all electronics for easy maintenance. In addition, with 10 pluggable relays, 16 universal inputs, and 8 digital or thermostat inputs, it supports versatile configurations. Furthermore, direct RS485 thermostat connections are expandable via subnet or additional controllers. Moreover, the open-source front-end software is free to download, while BACnet over Ethernet/TCP and RS485 MSTP, along with Modbus over IP and RS485 RTU, ensure seamless industrial communication.

Features successfully implemented:

- High voltage pumps connect directly no external relays to install & wire

- Baseplate is passive all electronics are in the removable lid

- 10 pluggable relays for low or line voltage switching

- 16 universal inputs, 0-5V, 0-10V, thermister can be configured by software. 8digital inputs(24V AC) or 8 thermostat which can be adjusted by jumper

- 8 thermostats direct connect over RS485, more via subnet or by adding more boiler controller

- Open source front end software, free download and no licensing fees

- Bacnet over ethernet TCP and RS485 MSTP

- Modbus over IP and RS485 RTU

Future improvements:

OUTDOOR SENSOR

The outdoor sensor not only measures light, humidity, and temperature, but also offers 3-point humidity calibration. In addition, it is network-programmable, allowing easy in-system configuration for accurate and reliable environmental monitoring.

Features successfully implemented:

- Light sensor, Humidity sensor, Temperature sensor

- 3 point humidity calibration

- Moreover, the system is fully programmable over network communication, enabling easy remote configuration and control.

Future improvements:

PWM TRANSDUCER

The PWM transducer converts a 0–10 second input pulse into a 0–10V DC signal and supports manual, OFF, or auto operational states. In addition, it offers optional RS485 communication, isolated input-to-output signaling, and edge-triggered activation. Furthermore, it interfaces with electric actuators to drive variable speed pumps and frequency fans, while a dial potentiometer allows manual override for precise control.

Features successfully implemented:

- Convert a 0~10seconds input pulse to a 0~10Vdc signal

- Manual/OFF/Auto operational states

- Optional RS485 communication

- Input to Output Signal Isolated

- Input Edge Triggered Activated

- Pulse to Analog Transducer

- Interface to Electric Actuator

- Drive Variable Speed Pump Control

- Drive Variable Frequency Fan Control

- In addition, the dial potentiometer allows manual override of the output, providing precise control whenever needed.

Future improvements:

In addition, our OEM projects streamline complex HVAC operations, while simultaneously providing scalable and flexible solutions. Moreover, by leveraging cutting-edge technology alongside robust design, they enhance system reliability, improve performance, and elevate the overall user experience. At the same time, these solutions offer seamless integration across diverse systems, ensuring that businesses can adapt quickly to evolving operational requirements. Consequently, organizations benefit from smoother workflows, reduced errors, and improved overall efficiency.

Furthermore, these projects enable businesses not only to minimize downtime and lower maintenance costs but also to achieve significant energy savings. In turn, this supports sustainability goals and reduces operational expenses over the long term. As a result, companies are empowered to optimize resources, increase productivity, and maintain a competitive edge. Ultimately, our OEM solutions foster long-term growth, operational excellence, and enduring sustainability across the HVAC industry.